1

/

of

5

Sal Ammoniac Block (8 oz)

Regular price

$12.66 USD

Sale price

$12.66 USD

Regular price

Unit price

/

per

Sale

Sold out

Shipping calculated at checkout.

In stock (970 units), ready to be shipped

Couldn't load pickup availability

-

Vendor:

My Store

- Tags: 8 oz, Ammoniac, Block, Care, Iron tips, Sal, Soldering tools, Terri brush design classes, Tinning, Tips

Description

Ensure your soldering iron tips are always in peak condition with this Jumbo 1/2 Lb. Sal Ammoniac Block. Specially designed for cleaning and re-tinning iron-clad soldering tips, this block enhances the performance and longevity of your soldering iron by maintaining a smooth, even tin coat.

Why Use the Sal Ammoniac Block?

- Cleans and Re-Tins: Removes oxidation and applies a fresh tin coating, helping your soldering iron deliver consistent heat and better solder flow.

- Improves Tip Longevity: Keeps tips working faster and lasting longer by preventing corrosion and wear.

- Essential for Lead-Free Soldering: Provides extra care for tips used with tough lead-free solder, which can be harsh on tip surfaces.

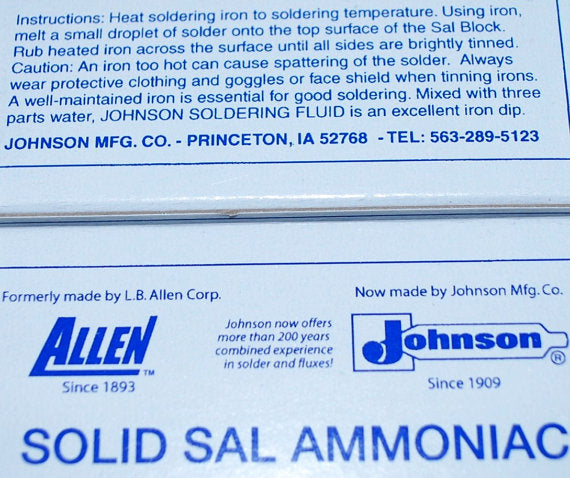

How to Use:

- Re-Tin Regularly: Melt a bead of solder onto the block and press your hot iron tip into it to create a fresh tin layer.

- Avoid Abrasive Cleaning: Wipe with a wet rag instead of harsh scrubbers to prevent tip damage.

- Skip the Flux Dip: While flux may clean, it’s too harsh for regular use and can shorten tip life.

- Prevent Tip Freezing: Remove your tip occasionally to clear any buildup inside the barrel and prevent it from getting stuck.

Key Features:

- Ideal for maintaining the exposed iron cladding on modern iron-clad tips.

- Works as a tinning block to ensure a clean, efficient soldering experience.

- Helps maximize heat transfer by maintaining a smooth tip surface.

Keep your soldering tips in top shape and achieve flawless results every time with this essential Sal Ammoniac Block!